- Categories

- Spiral wound gasket SMT-211

- SMT-211

Spiral wound gasket

Enquiry Now Spiral wound gasket Details

Spiral wound gaskets are special semi-metallic gaskets of great resilience. They're manufacured by spirally winding a V-shaped or W-shaped metal strip and a strip of non-metallic filler material. Spiral wound gaskets can be reinforced by an outer centering ring and/or inner retaining ring. The outer centering ring controls the compression and holds the gasket centrally within the bolt circle. The inner retaining ring increases the axial rigidity and resilience of the gasket. Spiral wound gaskets can be used for sealing flange joints, manhole and handhold covers, tube covers, boilers, heat exchanges, pressure vessels, pumps, compressors and valves. In indstries such as petrochemical, pharmaceutical, shipbuilding, and food processing, in power industries and nuclear power stations. They are ideal for steam, oil, liquids, gases, acids, alkalines, various organic mediums and solvents.

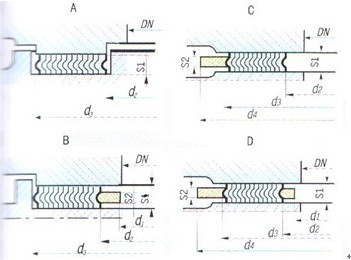

Gasket standard style:

TYPE A without outer and inner ring

TYPE B only with inner ring

TYPE C only with outer ring

TYPE D with outer and inner ring

Metallic strip material 0.2mm thickness:

SS304, SS316L, SS347, Monel, Alloy 600, Hastlloy C276, Ti grade 2, Ti grade 7;

other material on request.

Filler strip material 0.5-0.6mm thickness: Flexible graphite, PTFE, Asbestos, Non-asbestos.

Outer ring and inner ring material:

CS, SS304, SS316L, SS347, Monel, Alloy 600, Hastlloy C276, Ti grade 2, Ti grade 7,

other material on request.

Dimensions standard: ASME, BS, DIN, JIS standard,

and other size as per clients' request.

- You may also like (Related items of Spiral wound gasket)

- Spiral wound gasket has been presented above, want more related products, please click the category below.

Category: Spiral Wound Gasket

Related category: - Bookmark this pagePrint this page

SMT-212

SMT-212